+86 25 6959 8899

+86 25 6959 8899

sales@chamlion.com

sales@chamlion.com

2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

As metal 3D printing becomes more established and restorative materials continue to evolve, a shift is taking place in how removable dentures are designed.

Rather than focusing solely on strength, the industry is increasingly asking whether lighter and more comfortable solutions can be achieved without compromising mechanical safety.

A recent case from Chamlion offers a clear answer.

A titanium framework weighing just 2 grams demonstrates what is now possible.

Lightweight design is not simply about “reducing weight”

It is about rethinking the entire system.

From a clinical perspective, this case presented favorable conditions for lightweight optimization: limited abutment tooth loss and sufficient lingual vestibular depth. Based on these anatomical characteristics, the design team adopted a lingual bar structure, positioning it away from the gingival margin to minimize soft tissue compression while maintaining good self-cleansing performance.

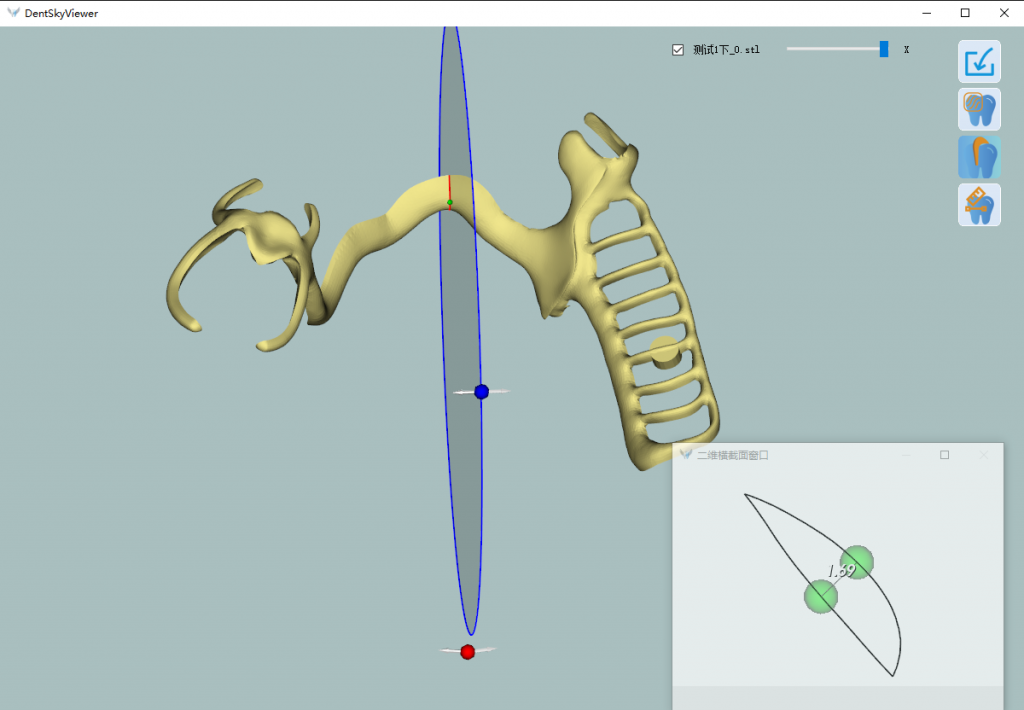

Within the required mechanical safety margins, the lingual bar was further optimized for thinness, with thickness controlled at 1.69 mm. The result is a significant reduction in foreign-body sensation. For patients, this translates into a shorter adaptation period and improved comfort. For clinicians, it represents a meaningful step forward in balancing function and wearability.

Importantly, this kind of “lightness” is not achieved by simply removing material. It is built on a systematic understanding of structure, force distribution, and real-world wearing scenarios.

Titanium is becoming more common, but using it well remains the real challenge

As metal 3D printing equipment becomes more widely available, titanium is increasingly adopted in dental restorations. On the surface, the barrier to entry appears lower. In reality, however, there is a clear gap between being able to print titanium and being able to use it reliably and consistently for removable dentures.

Titanium demands extremely high standards in printing parameters, energy control, forming stability, and post-processing consistency. These requirements become even more critical in lightweight, thin-wall designs, where minor deviations can directly affect strength, fit, and long-term reliability. This is precisely why titanium printing has remained a technical barrier for so long.

Behind this titanium framework lies years of accumulated expertise by Chamlion in 3D printing. From the in-house development of intelligent framework design software DentSky, to the establishment of standardized design protocols; from early deployment of titanium 3D printing systems to validation through tens of millions of printed cases, lightweight design is not the result of a single parameter optimization, but the outcome of a fully integrated manufacturing capability.